FOLDING FLAT PACK CONTAINER HOUSE

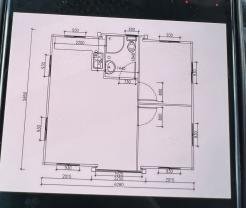

| Type | Open Size | Folded Size | Total Area(㎡) | Order Quantity |

|

|

|

| A | 6320*5900*2480mm | 2200*5900*2650mm | 37.3 |

|

|

|

| Characteristic | LIFE SPAN | more than 30 years |

| WATER PROOF | 99.9999% |

|

| EARTHQUAKE RESISTANCE | Grade 10 |

| SOUND RESISTANCE | ≥30dB |

|

| HEAT INSULATION | 0.506317W/(m^2·K) |

| WIND RESISTANCE | ≥120KM/Hour |

|

| ROOF LIVE LOAD | ≥1.0KN/㎡ |

| FLOOR LIVE LOAD | ≥2.5KN/㎡ |

|

| FIREPROOF GRADE | A |

|

|

|

|

| FRAME STRUCTURE | Middle Container | Top and bottom upright beams | 210*150*2.5mm and 80*100*2.5mm P shaped beams Q235B |

|

| Top and bottom cross beams | 2.5mm shaped beams(Q235B) |

|

| top purlins | 40*60*2.5mm Q235B |

|

| bottom purlins | 40*80*2.5mm Q235B |

|

| side beams | 80*100mm Q235B |

|

| Side Containers | Top and bottom vertical beams | 40*60*2.5mm P shape Q235B |

|

| top and bottom cross beams | 40*60*2.5mm P shape Q235B |

|

| bottom purlins | 40*80*2.0mm Q235B tubes |

|

| side wall frames | 40*60*2.5mm Q235B tubes |

|

| WALL PANELS | MIDDLE CONTAINER TOP PANEL | T75mm glass wool sandwich panel(side EPS panels) |

|

| SEPERATING PANELS | T50mm EPS sandwich panel |

|

| FLOORING | Fireproof glass magnesium floor 15mm+1.5mm PVC floor leather |

|

| OTHERS | FOLDING HINGE

HANGING HEAD | T4mm,Q235B |

|

| FOLDING HINGE | 13mm,galvanized |

|

| TOP CONTAINER EXTERNAL SHEET | T0.5mm gal.steel sheet |

|

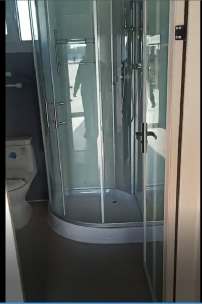

| ELECTRIC SYSTEM | 6-hole USA-standard sockets with double-switches for each house&with 2 air conditioner sockets with 4㎡ copper electric lines&5 LED lights(1 for each bedroom&1 for bathroom&1 for kitchen&1 for living room) |

280mm dia for bathroom&350mm for other rooms |

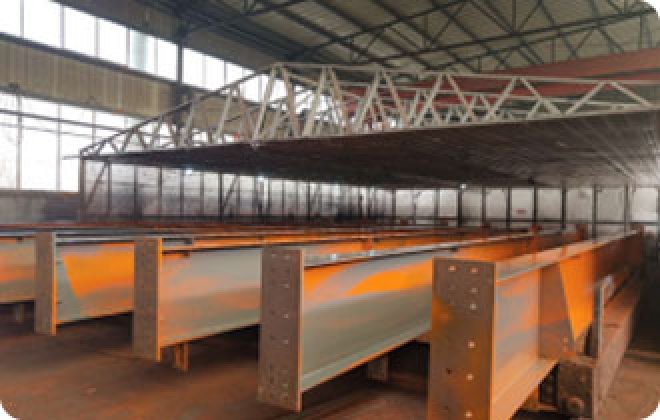

Steel Structure Manufacturing Plant Characteristics:

1. Wide span: single span or multiple spans, the max span is 36m without middle column.

2. Low cost: Unit price range from USD35/m2 to USD70/m2 according to customers' request.

3. Fast construction and easy installation.

4. Long using life. up to 50 years.

5. Easy construction, time-saving, and labor saving

6. Flexible layout, beautiful appearances, and higher space efficiency

7. Be used as warehouses, workshops, shopping mall, dinning hall, stadium, etc.

8. Others: environmental protection, stable structure, earthquake proofing, water proofing, and energy conserving.

How To Build A Prefabricated Steel Structure Warehouse?

You should give us the following data:

1)Design Data

1.live load on roof(KN/M2)

2.wind speed(KM/H)

3.snow load (KG/M2) if have

4.earthquake load if have

5.crane (if have), lift height, lift capacity,

2)Size

1.width

2.length

3.eave height

4.roof slope

3)Type

1.single slope OR double slope

2.muti slope OR single span

3.double-span OR Multi-span

4.single floor OR two floors

4)Intercolumn

5m, or 6m….

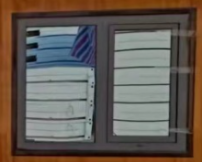

5)Windows &Door

1.quantity

2.size

3.Location

4.PVC or aluminum

6)Column &Beam

straight cross-section OR Variable cross-section

7)Roof & Wall Panel

1.colorfull corrugated steel sheet 0.326~0.8mm thick ,YX28-205-820(820mm wide),

2.sandwich panel with EPS,ROCK WOOL,PU etc, insulation thickness around 30 ~300mm,

3.sheet+glass fiber(thick 50mm~200mm)

8)Purlin

1.C purlin size:120~C320,Z

2.purlin size100~Z200

9)Accessories

Do you need the skylight belts, Ventilators, down pipe, out gutter etc?

10)Surface Treatment

Shot blasting with anti rust paint or hot dip galvanize